Technology

Precision Technology for Superior Railing Systems

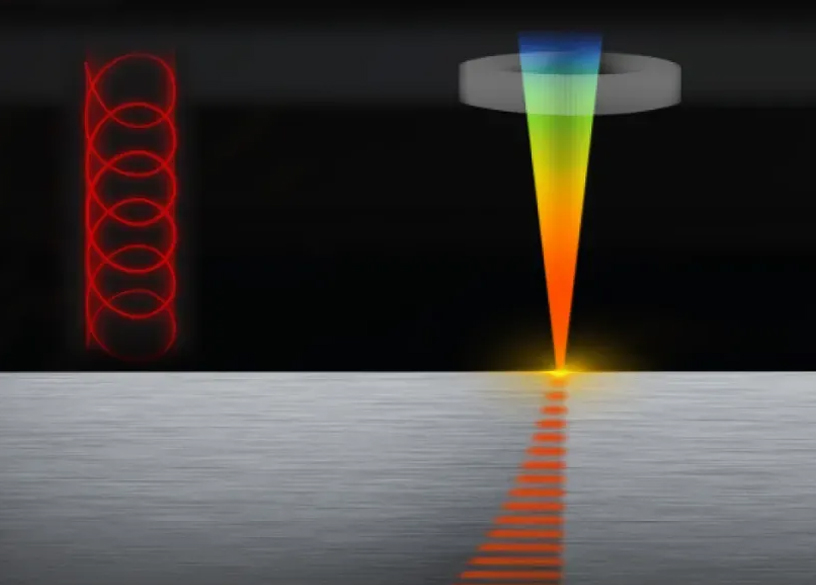

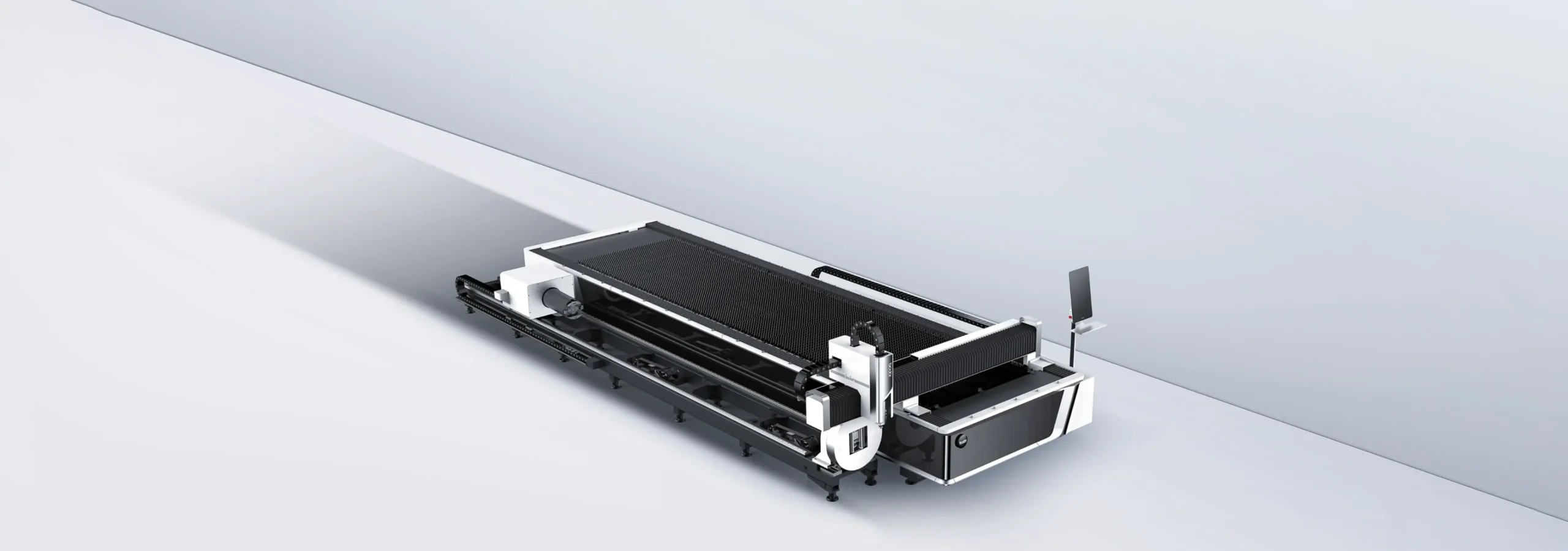

At NNL Railing, we believe precision and quality go hand-in-hand. That’s why we invest in advanced technology like our Fiber Laser Cutting System, a state-of-the-art machine that allows us to achieve unmatched accuracy and efficiency in both sheet and tube aluminum fabrication.

Some of our other technologies include:

- "Concrete x-rays"

- Stud welders

-

Leica BLK360 Scanner for accurate measurements

-

Streamlined submittals

-

Over 40 years of engineering experience

What We Use It For

Technology Highlights

-

Dual-Use Functionality: Capable of cutting both metal sheets and tubes with high precision

-

Automatic Loading & Unloading: Enhances production speed and reduces material handling errors

-

Seamless Switching: Easily transitions between profiles and materials, ensuring flexibility for custom work

-

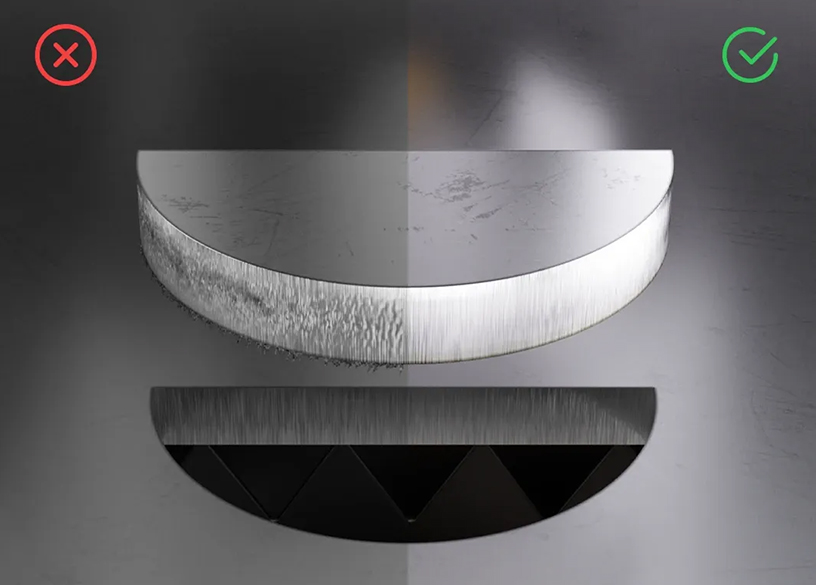

High-Speed Cutting: Achieves clean edges and smooth finishes faster than traditional methods

-

Efficient Production: Reduces waste and improves consistency for large and small-scale fabrication

How We're Different

Precision cutting isn't just about speed—it’s about the confidence that every post, panel, and component fits perfectly, performs flawlessly, and looks exceptional. Our investment in cutting-edge technology ensures we maintain the highest standards of quality for architects, general contractors, and property owners.

Whether it’s a simple picket system, a modern glass railing, or a fully custom perforated metal design, our laser technology helps bring your project vision to life with accuracy, efficiency, and craftsmanship you can trust.